According to its use function, beixinyuwang hot melt modified asphalt waterproof rolling material can be divided into ordinary type, root and piercing resistant type, salt and alkali resistant type, road and bridge special type, decorative type, etc., applicable to a wide range of fields

MODIFIED ASPHALT WATERPROOF ROLL (HOT MELT SERIES)

YWR-471

Salt-alkali Resistant Polymer Modified Bitumen Waterproof Membrane

Modified Asphalt Waterproof Roll (Hot Melt Series)

★ Product Description download

10.0 7.5

Length /m:

1.0

Width /m:

4.0 5.0

Thickness/mm:

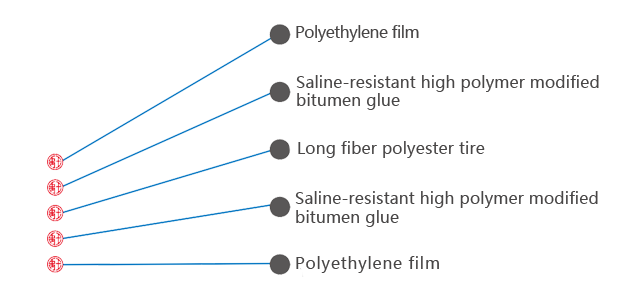

Divided into polyethylene film (PE) and fine sand (S) according to the surface material.

Product Specification:

————

The product is a waterproof membrane made of long-fiber polyester felt as the base, SBS as the main modified enamel and adding functional modifier, and modified asphalt as the coating material. The product meets the advantages of the national standard SBS elastomer modified asphalt waterproofing membrane. At the same time, it also adds anti-gas ion penetration and salt and alkali corrosion resistance. It is the first choice material for building waterproof engineering in coastal and strontium-salt areas.

PRODUCT

INTRODUCTION

FEATURES

PRODUCT

Pay attention to controlling the flame during construction and heat it evenly.

Hot melt construction

Construction by hot melt method. That is, a flame spray gun is used to bake the hot melt adhesive of the bottom layer of the coil for bonding.

Hot melt construction

METHOD

CONSTRUCTION

Low temperature℃:-20,No crack

Size change rate/%≤0.7

Quality loss/%≤1.0

Thermal aging

≥1.0

Thickness of asphalt coating on lower surface of coiled material/mm

≤0.005

Chloride resistance permeability/(mg/cm³·d)

Tension/%≥90; Elongation/%≥90;Low temperature:-20℃,No crack

Salt tolerance(at 20% NaCI and saturated Ca (OH)2)

≥1.5

Joint peel strength/(N/mm)

≤2

Oil permeability / number of sheets

Tension retention rate%:90

Elongation retention /%≥80

Thermal aging

≤1.0

Mass increase after immersion/%

≥300

Tear strength/N

≥40

Maximum peak time elongation%

≥800 During the tensile process, there is no crack of asphalt coating or separation from the tire base in the middle of the test piece

Maximum peak tension/(N/50mm)

105

There is no flowing and dropping phenomenon, and the sliding ridge is≤2mm

Heat resistance/℃

0.3

120min Impervious

Water impermeability/MPa

4mm 5mm

≥2900 ≥3500

Soluble content﹙g/㎡﹚

Physical Index

The requirements of Q/PYW 0072 《Salt-Resistant Polymer Modified Bitumen Waterproof Membrane》are met; and the performance requirements of JTJ 275-2000 《Technical Specifications for Corrosion of Concrete Structures in Seaport Engineering》 are met.

STANDARD

EXECUTIVE

-25

No crack

Low temperature flexible/℃

It is especially suitable for waterproofing of underground buildings and tunnels, caverns, oil depots and other projects in coastal areas and high salinity areas.

FIELD

APPLICATION

From Monday to Saturday at 8:00am -18:00pm

Email :wugang@bnbm.com.cn

Address: South of Xingyou Street, West of Jinger Road, Xinglongtai District, Panjin City, Liaoning Province, China

400-600-0427

Contact us

Hydro power

Municipal building

Commercial building

Civil building

Bridge, tunnels and roads

Overseas engineering

Rail roads and subways

Major projects

Classical engineering cases

Waterproof coating ranges

Excellent and Secure Waterproofing System Ranges

Polymer ranges of waterproof materials

Self adhering ranges of modified asphalt waterproof membrane

Hot-torched ranges of modified asphalt waterproof membrane

Products center

Development history

Honor

Enterprise culture

Production bases

Company introduction

Enter BNBM Yuwang