According to its use function, beixinyuwang hot melt modified asphalt waterproof rolling material can be divided into ordinary type, root and piercing resistant type, salt and alkali resistant type, road and bridge special type, decorative type, etc., applicable to a wide range of fields

MODIFIED ASPHALT WATERPROOF ROLL (HOT MELT SERIES)

YWR-453

Polymer Modified Bitumen Waterproof Membrane for High-speed Rail

Modified Asphalt Waterproof Roll (Hot Melt Series)

★ Product Description download

————

≥20

Length/m:

1.0-2.2

Width/m:

4.5

Thickness/mm:

Product Specification:

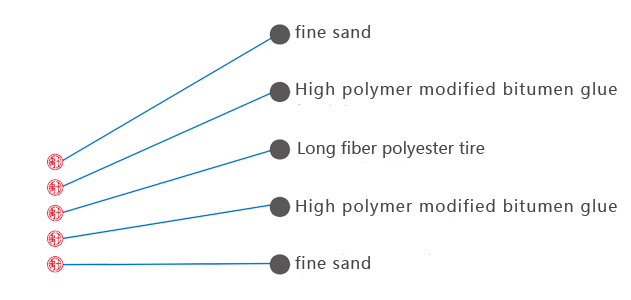

The product is made of long-fiber polyester felt as the base material, high-polymer modified asphalt as the coating material, and double-sided coated with fine sand insulation material. The material has high strength, large elongation and excellent heat resistance, flexibility and shear resistance. It can withstand long-term load movement of roads and bridges, prevent structural damage caused by water seepage, steel corrosion, concrete carbonization, and greatly extend the service life of roads and bridges.

PRODUCT

INTRODUCTION

FEATURES

PRODUCT

1. Coil positioning and elastic wire.

2. The coil is pre-laid at the position of the elastic line, releasing the stress, rolling the coil from the two ends to the middle, uniformly baking the bottom layer and the base layer of the coil with a flame spray gun, and winding the coil from the middle to the both ends of the coil. Paving, compacting while laying, excluding air, so that the coil and the base layer are firmly bonded.

3. There should be natural overflow of molten asphalt at the lap joint to ensure that the lap joint is firmly attached. The longitudinal length of the web shall not be less than 100mm.

4. The waterproof membrane should be laid on the bridge deck to the retaining wall and the root of the vertical wall.

5. The lap and the end of the place to do a good job of sealing. Matters needing attention: Rain and snow days and five windy days are not allowed to be constructed; the construction environment temperature of coiled materials should not be lower than -10 °C.

Construction steps:

Base layer requirements: Before laying the coil, the surface of the base layer should be removed from the slurry and dust; the surface of the base should be dry, free of oil and solid.

Processing the base layer: Before the coil material is applied, the high-polymer modified asphalt base layer treatment agent should be applied to the base layer, and the base layer treatment agent should be evenly coated, not exposed, and not stacked; when the base layer treatment agent is dry and not sticky, For the paving of the coil, it is recommended to use not less than 0.4kg per square meter.

Hot melt construction

METHOD

CONSTRUCTION

High-iron special high polymer modified asphalt waterproof coil material physical property index.

No creak

Low temperature flexibility(-5℃,φ10㎜ rod)

≥0.80

Bond strength

(MPa,20℃)

No runny, bubbling, sliding

Heat resistance(80℃,5h)

≤2

Drying time (h)

≥30

Solid content(%)

≥210

Tension (vertical and horizontal)/(N/cm)

≥10.0 or coil destruction

Adhesion in the typical state/(N/mm)

No water seepage

Perforation resistance

-30,No crack

Low temperature bending/℃

≥450

Tear Strength/N

≥50

Extensibility at maximum tension(vertical and horizontal)/(%)

115 No runny、 No dripping, sliding≤2mm

Heat resistance/℃

0.4

120min,Impervious

Water impermeability/MPa

4.5mm≥3100

Soluble content/﹙g/㎡﹚

Physical properties of polymer modified bitumen base treatment agent.

Physical Index

TB/T2965-2018《Technical Conditions for Waterproof Layer of Railway Concrete Bridge Deck》

STANDARD

EXECUTIVE

It is suitable for anti-corrosion, anti-seepage and waterproof of high-speed railway, highway, culvert and concrete bridge deck engineering.

FIELD

APPLICATION

From Monday to Saturday at 8:00am -18:00pm

Email :wugang@bnbm.com.cn

Address: South of Xingyou Street, West of Jinger Road, Xinglongtai District, Panjin City, Liaoning Province, China

400-600-0427

Contact us

Hydro power

Municipal building

Commercial building

Civil building

Bridge, tunnels and roads

Overseas engineering

Rail roads and subways

Major projects

Classical engineering cases

Waterproof coating ranges

Excellent and Secure Waterproofing System Ranges

Polymer ranges of waterproof materials

Self adhering ranges of modified asphalt waterproof membrane

Hot-torched ranges of modified asphalt waterproof membrane

Products center

Development history

Honor

Enterprise culture

Production bases

Company introduction

Enter BNBM Yuwang