According to its use function, beixinyuwang hot melt modified asphalt waterproof rolling material can be divided into ordinary type, root and piercing resistant type, salt and alkali resistant type, road and bridge special type, decorative type, etc., applicable to a wide range of fields

MODIFIED ASPHALT WATERPROOF ROLL (HOT MELT SERIES)

YWR-435

Stereoscopic Modified Bitumen Waterproof Membrane

Modified Asphalt Waterproof Roll (Hot Melt Series)

★ Product Description download

7.5 5.0

Length/m:

1.0

Width/m:

4.0 5.0

Thickness/mm:

According to physical and mechanical properties, it is divided into type I and type II.

Product Specification:

————

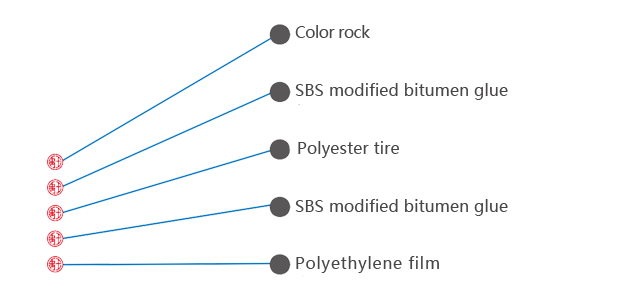

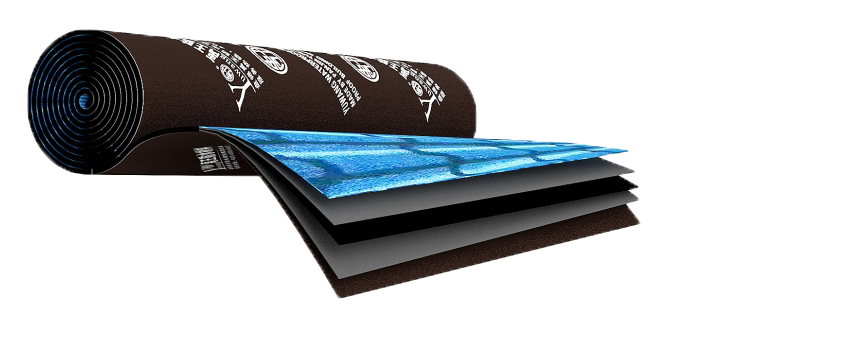

The “Three-dimensional Colorful Sand Covering” production line of Beixin Yuwang is a newly developed high-efficiency automated production system from the raw material blending and sand-covering surface and pattern controlled by computer. The three-dimensional colorful modified asphalt waterproofing membrane produced by the company. "The filament polyester felt is used as the carcass. After dip coating high quality SBS modified asphalt compound, it adopts the international leading professional production technology, and is coated with polyethylene film on one side and covered with colored mineral particles. Graphic, colorful three-dimensional decorative effect covering. It is an upgraded product of traditional waterproofing membranes and asphalt shingles. It is the latest international waterproofing material that integrates roof decoration, waterproof, energy saving and consumption reduction functions

PRODUCT

INTRODUCTION

FEATURES

PRODUCT

The coil is rolled from the two ends to the middle, and the hot melt adhesive of the bottom of the coil is baked with a flame spray gun, and the coil is laid from the middle to the both ends, and the paving is compacted by a press roll to remove air, so that the coil is adhered to the base layer. The knot is firm, the lap joint should overflow the hot-melt modified bitumen, the lap joint of the color rock surface should be grit-treated, the detail node should be additionally treated, and the lap joint and the head end should be sealed.

Hot melt construction

The hot-melt method is adopted, before the construction, the base layer treatment agent (full-adhesive method) should be evenly applied, and then the elastic direction of the construction direction should be determined to determine the position of the coil material, and the coil material is unfolded at the position of the elastic line to release the stress.

Hot melt construction

METHOD

CONSTRUCTION

0.3

Keep time 30min Impervious

Water impermeability/MPa

-20℃,No crack

-25℃,No crack

Low temperature flexibility /℃

≥500 ≥800

Tension (vertical and horizontal)/(N/mm)

90 105

No runny、 No dripping,sliding≦2mm

Heat resistance/℃

4mm 5mm

≥2900 ≥3500

Soluble content/(g/㎡)

Physical Index

GB 18242-2008《three-dimensional colorful modified asphalt waterproofing membrane》

STANDARD

EXECUTIVE

≥30 ≥40

Elongation at maximum tensile force (vertical and horizontal)/%

Waterproofing and decoration of slope roofs for industrial, civil and military (hidden) buildings.

FIELD

APPLICATION

From Monday to Saturday at 8:00am -18:00pm

Email :wugang@bnbm.com.cn

Address: South of Xingyou Street, West of Jinger Road, Xinglongtai District, Panjin City, Liaoning Province, China

400-600-0427

Contact us

Hydro power

Municipal building

Commercial building

Civil building

Bridge, tunnels and roads

Overseas engineering

Rail roads and subways

Major projects

Classical engineering cases

Waterproof coating ranges

Excellent and Secure Waterproofing System Ranges

Polymer ranges of waterproof materials

Self adhering ranges of modified asphalt waterproof membrane

Hot-torched ranges of modified asphalt waterproof membrane

Products center

Development history

Honor

Enterprise culture

Production bases

Company introduction

Enter BNBM Yuwang