According to its use function, beixinyuwang hot melt modified asphalt waterproof rolling material can be divided into ordinary type, root and piercing resistant type, salt and alkali resistant type, road and bridge special type, decorative type, etc., applicable to a wide range of fields

MODIFIED ASPHALT WATERPROOF ROLL (HOT MELT SERIES)

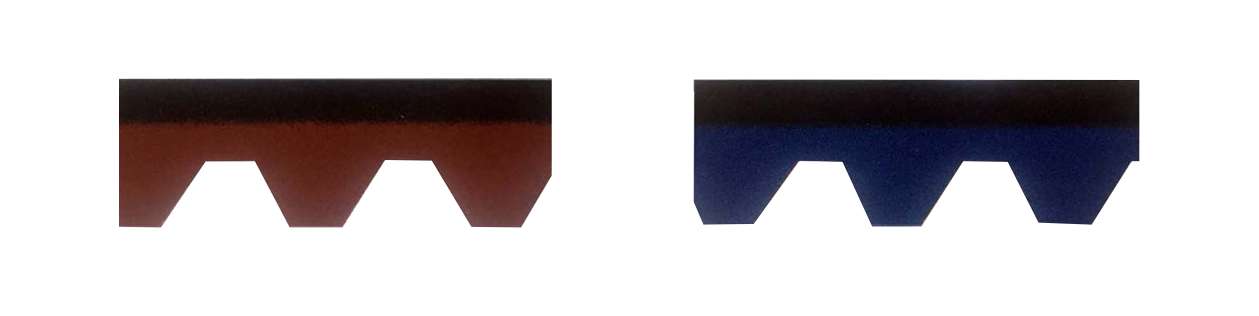

MPG-401 Fiberglass Bitumen Shingle

Product Description download

★ Product Description download

1.0

Length/m:

0.333

Width/m:

≥2.6

Thickness /mm:

Divided into flat tile (P) and tile (L) by product form.

Product Specification:

————

The product is made of glass fiber mat as the base, dip coated with high-quality petroleum asphalt, covered with colored mineral pellets on one side, and tile-shaped roof waterproof sheet made of insulating material on the other side.

PRODUCT

INTRODUCTION

FEATURES

PRODUCT

Construction method: A layer of asphalt waterproofing membrane cushion should be laid on the base layer before laying the tile. Before laying the first layer of colored asphalt linoleum, the initial layer should be laid first (the mouthwash plate should be set at the mouth of the mouth). The initial layer tile is made of colored asphalt. The linoleum tile is cut off from the tile skirt, and the initial layer is laid directly along the bottom of the roof. The side with the adhesive glue is facing upwards and is biased toward the crevice. The surface contact with the roof is coated with special adhesive for asphalt tile and linoleum is used. The nail (or cement nail) is fixed on the roof. The wooden base layer is fixed with linoleum nails, and the concrete base layer is fixed with cement nails. When laying the ridge tiles, fix them with two linoleum nails (or cement nails); the ridge tiles should be lapped at the maximum frequency of the year, and should cover 1/3 of the joints of the two slopes of asphalt shingles; ridges and ridges The gland surface should not be less than 1/2 of the area of the ridge tile.

Materials and implements: linoleum nails (or cement nails), special adhesives for asphalt shingles; elastic boxes, tape measures, hand hammers, and paper cutters.

Base treatment: The treated substrate should be firm, flat, clean and dry. The surface of the concrete base should be smeared with 1:3 cement mortar leveling layer.

Detail node processing: The joints at the intersection of the base layer and the protruding roof structure and the corners of the roof are rounded and the additional layer is laid.

Hot melt construction

METHOD

CONSTRUCTION

≥20

Laminated peel strength/N

50℃:Sticky

75℃:Sliding≤2mm

Self-adhesive heat resistance

Pass

Wind resistance performance (97km/h}

≤1.0

Mineral material viscosity/g

≥75

Nail resistance pullout performance/N

impermeable

Impervious (2m water column, 24h)

≥9

Tear strength/N

90 No drooling, sliding, dripping, bubbles

Heat resistance/℃

Portrait Landscape

≥600 ≥400

Tension/(N/50mm)

Flat tile Tile

≥800 ≥1500

Soluble content/(g/㎡)

Physical Index

GB/T 20474-2015《Fiberglass Bitumen Shingle》。

STANDARD

EXECUTIVE

No crack

Flexibilityª(10℃)

The sloping roofs of buildings, such as public facilities, residential houses, villas, etc., which are suitable for important and general waterproof grades, are more suitable for the decoration and waterproofing of villas or special buildings composed of more complicated geometric shapes due to the flexibility of the products.

FIELD

APPLICATION

From Monday to Saturday at 8:00am -18:00pm

Email :wugang@bnbm.com.cn

Address: South of Xingyou Street, West of Jinger Road, Xinglongtai District, Panjin City, Liaoning Province, China

400-600-0427

Contact us

Hydro power

Municipal building

Commercial building

Civil building

Bridge, tunnels and roads

Overseas engineering

Rail roads and subways

Major projects

Classical engineering cases

Waterproof coating ranges

Excellent and Secure Waterproofing System Ranges

Polymer ranges of waterproof materials

Self adhering ranges of modified asphalt waterproof membrane

Hot-torched ranges of modified asphalt waterproof membrane

Products center

Development history

Honor

Enterprise culture

Production bases

Company introduction

Enter BNBM Yuwang