According to its use function, beixinyuwang hot melt modified asphalt waterproof rolling material can be divided into ordinary type, root and piercing resistant type, salt and alkali resistant type, road and bridge special type, decorative type, etc., applicable to a wide range of fields

MODIFIED ASPHALT WATERPROOF ROLL (HOT MELT SERIES)

YWR-583

APP Modified Bitumen Waterproof Membrane for Railway and Bridge

Modified Asphalt Waterproof Roll (Hot Melt Series)

★ Product Description download

10.0

Length/m:

1.0

Width/m:

3.5 4.5

Thickness/mm:

The products are divided into hot-melt (R) or hot-melt (J) construction waterproofing membranes according to the construction method. According to the form of asphalt pavement layer, it is divided into I open type and II type. The upper surface material of the coil is fine sand (S). The hot-melt construction waterproofing membrane is divided into polyethylene film (PE) and fine sand (S) according to the surface material. The material of the lower surface of the hot-melt adhesive construction waterproofing membrane is: fine sand (S).

Product Specification:

————

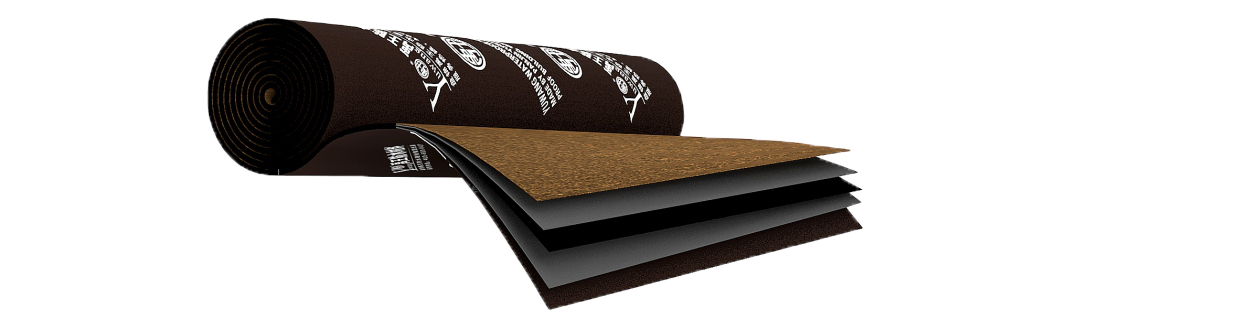

The product is based on long-fiber polyester felt as base material, and is made of plastic elastomer modified asphalt such as random polypropylene (APP) or polyolefin polymer (APAO, APO). Waterproof membrane. The material has high strength, large elongation and excellent heat resistance, flexibility and shear resistance. It can withstand long-term load movement of bridge deck, prevent structural damage caused by water seepage, steel corrosion, concrete carbonization, and greatly extend the use of bridge deck life.

PRODUCT

INTRODUCTION

FEATURES

PRODUCT

The coil is unfolded at the position of the elastic wire. The bottom layer and the base layer of the coil are baked with a flame spray gun, and the coil is laid. The edge is covered with a pressure roller to remove the air, so that the coil and the base layer are firmly bonded.

When the coil is constructed by hot melt method, the lap joint should overflow the hot melt modified bitumen.

Sealing is done at the lap and the end.

Notes:

● Construction is not allowed on rainy and snowy days and on windy days above Grade 5.

●The construction environment temperature of the coil should not be lower than -10 °C.

The base layer must be flat, rough, firm and fully dry, free of dust, oil and sharp corners.

Additional processing of detail nodes.

Brush the base treatment agent.

Then press the construction direction to determine the position of the coil.

The hot-melt coil material is constructed by hot melt method; the hot melt adhesive type coil material is constructed by hot melt adhesive method.

METHOD

CONSTRUCTION

10,000 cycles without damage

Seam deformation ability

0.1, 30min impervious

Impermeability after hot rolling/MPa

≥0.050

50℃bond strength/MPa

≥0.12

50℃shear strength/MPa

≤1

Oil permeability / number of sheets

Tension retention rate/%:≥90;Elongation retention rate/%:≥90;Low temperature flexibility/℃:-10/-5 No crack;Dimensional change rate/%:≤0.5;Quality loss/%:≤1.0

Heat aging

Tension retention rate/%:≥90

Low temperature flexibility/℃:-15/-10,No crack

Mass increase/%:≤1.0

Salt treatment

-15,No crack

-10,No crack

Low temperature flexibility/℃

≥40

Elongation at maximum tensile force (vertical and horizontal)/%

130 160

No sliding、No runny、 No dripping

Heat resistance/℃

3.5mm 4.5mm

≥1.5 ≥2.0

Thickness of the lower surface of the coil/mm

3.5mm 4.5mm

≥2400 ≥3100

Soluble content/(g/㎡)

Application Performance

Physical Index

JC/T974-2005《modified bitumen waterproofing membrane for road bridge》

STANDARD

EXECUTIVE

≥800

Tension (vertical and horizontal)/(N/50mm)

It is widely used in various types of road and bridge waterproofing engineering. It can be applied to paving and pouring two types of asphalt concrete paving construction, and is the material of choice for road bridge waterproofing. It is also suitable for waterproofing projects such as parking lots and airport runways.

FIELD

APPLICATION

From Monday to Saturday at 8:00am -18:00pm

Email :wugang@bnbm.com.cn

Address: South of Xingyou Street, West of Jinger Road, Xinglongtai District, Panjin City, Liaoning Province, China

400-600-0427

Contact us

Hydro power

Municipal building

Commercial building

Civil building

Bridge, tunnels and roads

Overseas engineering

Rail roads and subways

Major projects

Classical engineering cases

Waterproof coating ranges

Excellent and Secure Waterproofing System Ranges

Polymer ranges of waterproof materials

Self adhering ranges of modified asphalt waterproof membrane

Hot-torched ranges of modified asphalt waterproof membrane

Products center

Development history

Honor

Enterprise culture

Production bases

Company introduction

Enter BNBM Yuwang