BNBM Yuwang waterproof coating series products can be divided into polymer waterproof coating, polymer modified asphalt waterproof coating and polymer cement waterproof coating.

WATERPROOF COATING SERIES

FMJ -160

Non-curable Rubberized Bitumen Waterproof Coating

Waterproof Coating Series

★Product Description download

————

Non-curing rubber asphalt waterproof coating is based on high-quality petroleum asphalt, functional polymer modifier and special additive are mixed curing materials prepared by curing materials. It is a viscous colloid at room temperature. After heating, it is heated. The viscosity decreases and presents a flowing liquid state.

PRODUCT

INTRODUCTION

FEATURES

PRODUCT

1. It is strictly forbidden to heat with open flame.

2.When heating with electric heating equipment, the material should be stirred while heating after melting. It is strictly forbidden to heat for a long time to prevent the material from aging and precipitation due to excessive local temperature.

Precautions:

Before the construction of fmj-160 non curing rubber asphalt waterproof coating, heating equipment such as heater or barrel stripper shall be used for melting, and the heating temperature shall not exceed 170 ℃. If the non curing coating and hot-melt asphalt coil are used in combination, the coil shall be unfolded at the snap line position, rolled up after pre-laid alignment, scraped or sprayed with non curing coating, and the coil shall be bonded with the non curing construction; if the non curing coating and high molecular polyethylene polypropylene (polyester) coil or thin self-adhesive coil are used in combination, the coating and coil shall be selected to be synchronous according to the construction temperature Construction, or construction coating interval after a period of time construction coil.

Reference dosage: 1.0mm thick coating, total dosage of coating is about 1.3 ~ 1.5kg/㎡.

Packaging: closed iron barrel packaging, 20kg / barrel.

Spraying method,Scraping method

METHOD

CONSTRUCTION

0.6MPa,No channeling water

Anti-hydrophobic

65℃,No drooling, sliding, dripping

Heat resistance

-20℃,No crack

Low temperature flexibility

Dry bas:100% cohesive failure

Wet base:100% cohesive failure

Bonding performance

≥98

Solid content

≥180

Flash point

Physical Index

JC/T2428-2017《Non-cured rubber asphalt waterproof coating》

STANDARD

EXECUTIVE

≥15mm

Extensibility

It is mainly used for waterproofing and plugging projects such as underground, flat roof, subway, tunnel, culvert, road and bridge.

FIELD

APPLICATION

From Monday to Saturday at 8:00am -18:00pm

Email :wugang@bnbm.com.cn

Address: South of Xingyou Street, West of Jinger Road, Xinglongtai District, Panjin City, Liaoning Province, China

400-600-0427

Contact us

Hydro power

Municipal building

Commercial building

Civil building

Bridge, tunnels and roads

Overseas engineering

Rail roads and subways

Major projects

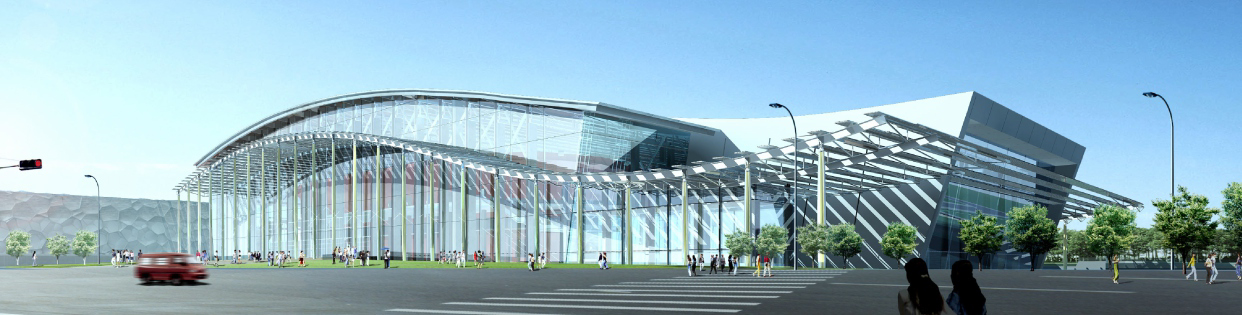

Classical engineering cases

Waterproof coating ranges

Excellent and Secure Waterproofing System Ranges

Polymer ranges of waterproof materials

Self adhering ranges of modified asphalt waterproof membrane

Hot-torched ranges of modified asphalt waterproof membrane

Products center

Development history

Honor

Enterprise culture

Production bases

Company introduction

Enter BNBM Yuwang