Polymer waterproof materials are one of the chemical building materials, with environmental protection and excellent physical and chemical properties, widely used in residential buildings, industrial and commercial buildings, water conservancy projects and underground engineering and other building waterproof engineering. Beixin waterproof polymer waterproof roll is made of synthetic rubber, synthetic resin or the blend of the two as the base material, adding the right amount of chemical additives and filler, using the processing technology of rubber or plastics such as mixing, extrusion or calendering can be rolled into sheets of waterproof material.

POLYMER WATERPROOF MATERIAL SERIES PRODUCTS

PVC Waterproof Membrane

Polymer waterproof material series products

★ Product Description download

1.2 1.5 1.8 2.0

Thickness/mm:

Product Specification:

————

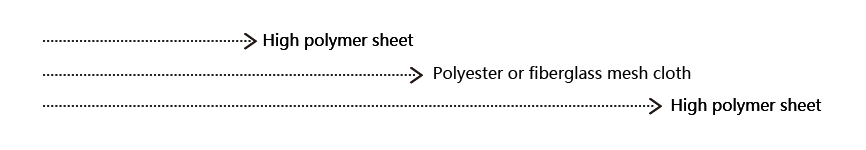

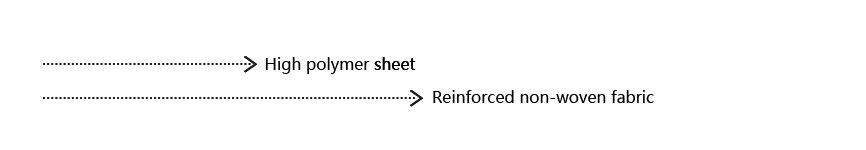

The product adopts PVC resin as the main raw material, adding plasticizer, stabilizer, antioxidant, anti - aging agent and other additives made of waterproof materials. The material has the characteristics of high strength, large elongation, but also has the advantages of good flexibility, can be used naked, at the same time has the ability of root resistance waterproof material.

PRODUCT

INTRODUCTION

Cold sticking method:The use of special supporting glue, the membrane paste on the base of the construction method, divided into full bonding or local bonding method. Finally, the membrane lap edge welding can be compacted.

Mechanical fixation method:The construction method of connecting the membrane with the base by mechanical fasteners. The membrane lap edge welding can be compact.

Construction Method

Machinery welding joint:The use of climbing welder for welding, suitable for large area construction, quick construction.

Hand welding joint:Hand-held welder is used for welding, suitable for detail construction and small area construction.Manual welding can be divided into three steps: "spot welding", "pre-welding" and "solid welding" to ensure the welding effect.Spot welding: used to fix the membrane and prevent the membrane from shifting. When spot welding, gently press the membrane surface with the tip of the gun.Pre-welding: it can seal, prevent hot air from blowing away, and can't reach the welding temperature.Solid welding: weld the two rolls of membrane into a whole.

Construction Method

METHOD

CONSTRUCTION

Planting roof application performance and requirements

≥50(H);-(L);

-(P);≥50(G);

-(GL)

Right-angled tearing strength(N/mm)

Retention rate after heat aging treatment/%

≥80 membrane damaged

Joint stripping strength

No processing/(N/mm):

Welding≥3.0 membrane damaged

Bonding≥1.5

Joint stripping strength

Mould proof level:level0 level1

Mold corrosion resistance

-(H、L);≥15(P);

-(G、GL)

Elongation at maximum tension/%

-(H);≥150(L);≥250(P);

-(G);≥220(GL)

Trapezoidal tearing Strength/N

≥50(H);

-(L、P);

≥50(G);-(GL)

Right-angled tearing strength(N/mm)

-25,no crack

Cold bending/℃

≥200(H);≥150(L);—(P);

≥200(G);≥100(GL)

Elongation at break/%

≤2.0(H);≤1.0(L);≤0.5(P);≤0.1(G);≤0.1(GL)

Heat treatment scale change rate/%

≥10(H);-(L、P);

≥10(G);-(GL)

Tensile strength/MPa

-(H);≥120(L);≥250(P);

-(G);≥120(GL)

Maximum tension/(N/cm)

-(H、L);

≥0.40(P、G、GL)

Thickness of resin layer above intermediate substrate/mm

Physical Index

GB12952-2011 PVC Waterproof Membrane;Root-puncture waterproof membrane meets all the requirements of class P in PVC (PVC) waterproof rolling material GB12952-2011;

Meanwhile, it also meets GB/ t35468-2017 planting roof root puncture resistant waterproof membrane.

STANDARD

EXECUTIVE

It is used in roof, underground, tunnel, subway, bridge, garbage dump, planting roof, artificial lake and other waterproof and impermeable projects.

APPLICATION FIELD

From Monday to Saturday at 8:00am -18:00pm

Email :wugang@bnbm.com.cn

Address: South of Xingyou Street, West of Jinger Road, Xinglongtai District, Panjin City, Liaoning Province, China

400-600-0427

Contact us

Hydro power

Municipal building

Commercial building

Civil building

Bridge, tunnels and roads

Overseas engineering

Rail roads and subways

Major projects

Classical engineering cases

Waterproof coating ranges

Excellent and Secure Waterproofing System Ranges

Polymer ranges of waterproof materials

Self adhering ranges of modified asphalt waterproof membrane

Hot-torched ranges of modified asphalt waterproof membrane

Products center

Development history

Honor

Enterprise culture

Production bases

Company introduction

Enter BNBM Yuwang