BNBM Yuwang waterproof coating series products can be divided into polymer waterproof coating, polymer modified asphalt waterproof coating and polymer cement waterproof coating.

WATERPROOF COATING SERIES

Type I and type II according to physical properties

Product classification:

Single Component Acrylic Waterproof Coating

Waterproof Coating Series

★ Product Description download

————

Acrylic waterproof coating is a single component water-based emulsion made from YISHION acrylic polymer emulsion and other additives. The waterproof film formed after the curing of waterproof coating has certain extensibility, elastoplasticity, crack resistance, impermeability and weather resistance, which can play the role of waterproof, anti-seepage and protection. Waterproof coating has good temperature adaptability, easy operation, easy maintenance and repair.

PRODUCT

OVERVIEW

FEATURES

PRODUCT

1. When the coating is not fully cured, it is strictly prohibited to get on or carry out the next construction.

2. Construction is strictly prohibited in rainy days, and contact with rainwater is strictly prohibited before film curing.

3. The construction temperature should be 5-35 ℃.

4. When it is used in the kitchen, bathroom and other humid environment, 5-10% cement can be added.

5. Reference dosage: 1.0mm thick coating, the dosage of coating is about 1.8-2.0kg/m2.

precautions

4. Large surface painting: during the construction of waterproof layer, painting can be carried out in several times according to the painting thickness, and the painting can only be carried out once before the painting is dry (generally 4-12 hours apart), and the painting direction of each time shall be perpendicular to each other.

5. Construction of protective layer: for the painted waterproof layer, protective measures shall be taken in time. After the waterproof layer is completely dry, closed water test shall be carried out. After acceptance, construction of protective isolation layer shall be carried out according to the design requirements.

Construction sequence: base course treatment → detail treatment → bottom coating → painting by stages.

1. Base treatment: the base shall be firm, flat and solid without sharp corners, floating ash, oil stains and obvious water stains. The internal and external corners shall be made into circular arc by cement mortar or sealing paste. Cracks in the base course and grooves at the pipe root shall be filled with sealing materials.

2. Primer treatment: in order to improve the construction cohesiveness, the primer shall be applied once before construction (without leakage).

3. Detail treatment: during the detail treatment, the fiber reinforced material shall be sandwiched between the coatings, so that the fiber reinforced material is fully soaked by the waterproof coating, and there shall be no white stubble or fold.

Spraying method, brushing method

METHOD

CONSTRUCTION

Elongation≤1.0

Shorten≤1.0

Heating expansion rate /%

Heating treatment/Alkali treatment/acid treatment/Artificial climate aging treatment

≥200/≥200/≥200/Ⅱ≥200

Elongation at break after treatment/%

Heating treatment/Alkali treatment/acid treatment/Artificial climate aging treatment

≥80/≥60/≥40%/Ⅱ≥80-150%

Tensile strength retention rate after treatment /%

≤8h

Hard drying time

≤4h

Surface drying time

≥65

Solid content/%

I:-10℃,Ⅱ:-20℃,

no cracking

Cold flexibility/℃, Bend 180 ° around φ 10 mm rod

≥300

Elongation at break,%

I≥1.0 Ⅱ≥1.5

Tensile Strength, MPa

Physical Properties

JC/T864-2008《polymer emulsion building waterproof coating》

STANDARD

EXECUTIVE

0.3MPa,30min,Impervious

Water impermeability

It is suitable for waterproof and anti-seepage engineering of roof, kitchen and bathroom, floor of various buildings.

FIELD

APPLICATION

From Monday to Saturday at 8:00am -18:00pm

Email :wugang@bnbm.com.cn

Address: South of Xingyou Street, West of Jinger Road, Xinglongtai District, Panjin City, Liaoning Province, China

400-600-0427

Contact us

Hydro power

Municipal building

Commercial building

Civil building

Bridge, tunnels and roads

Overseas engineering

Rail roads and subways

Major projects

Classical engineering cases

Waterproof coating ranges

Excellent and Secure Waterproofing System Ranges

Polymer ranges of waterproof materials

Self adhering ranges of modified asphalt waterproof membrane

Hot-torched ranges of modified asphalt waterproof membrane

Products center

Development history

Honor

Enterprise culture

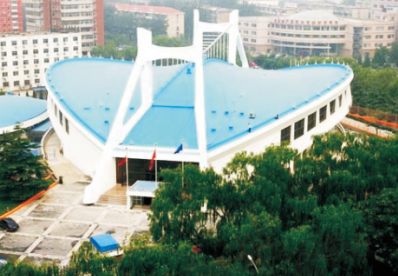

Production bases

Company introduction

Enter BNBM Yuwang